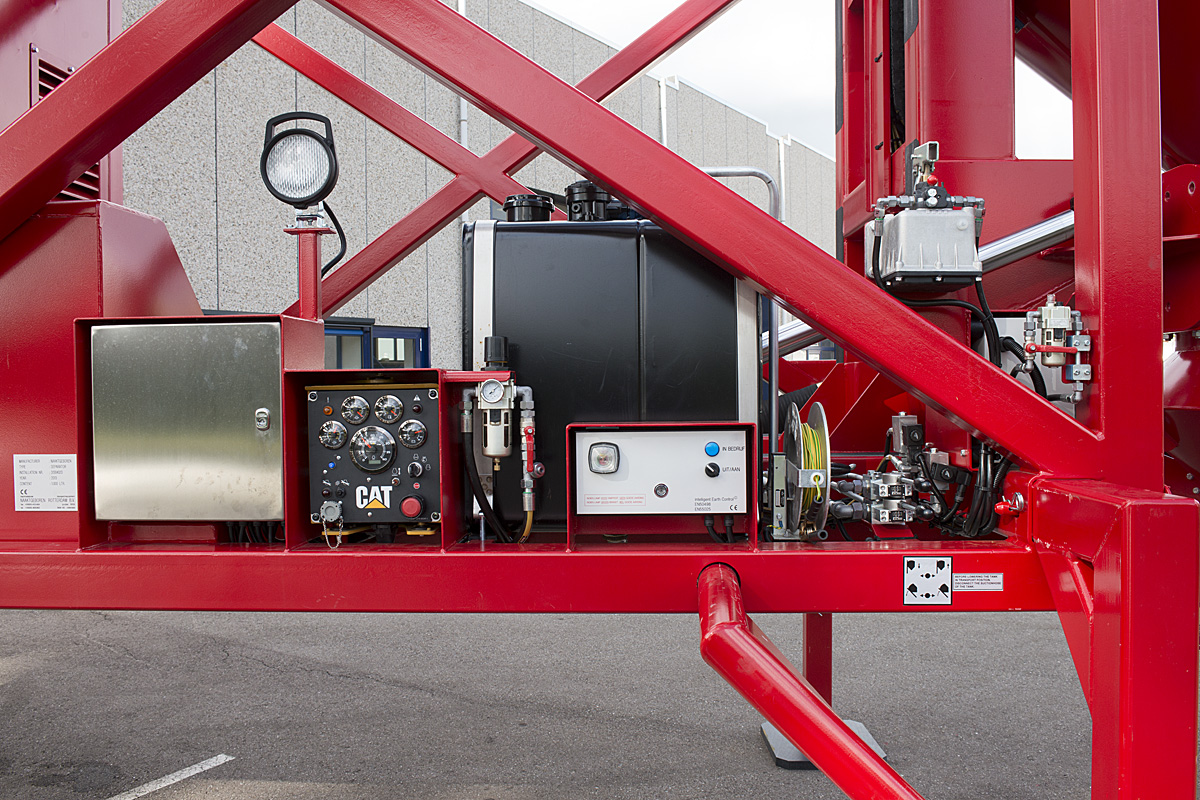

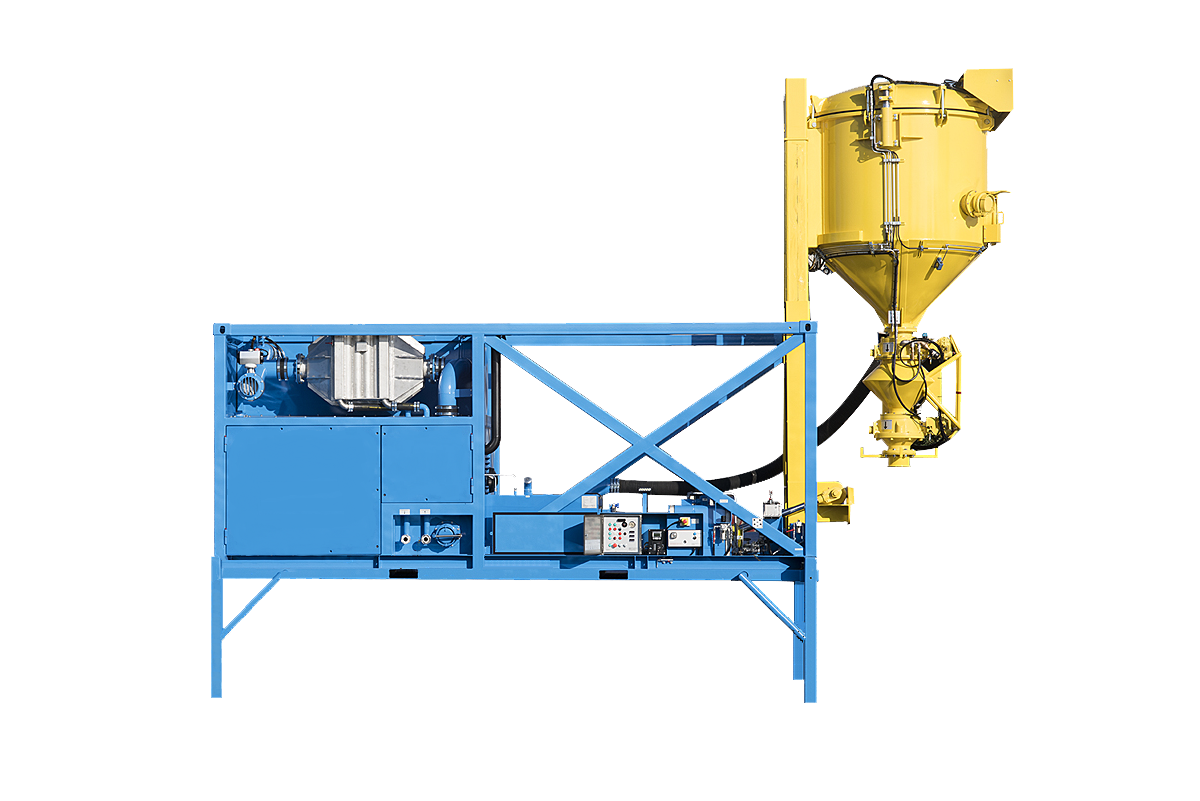

Vacu-Press® Catalyst Vacu-Press catalyst installations are standard built in a 20 ft. ISO container frame or as a trailer. The unit is brought into action in an environment where fire hazard should absolutely be avoided. This catalyst unit makes it possible because oxygen is eliminated by introducing nitrogen into the system to minimize combustion. During the filling of a silo it is possible to unload the material by using a double dome valve in the discharge system. Vacu-Press® Catalyst filter compartment: stainless steel type-304 ISO 20ft containerframe with Twistlocks / semi-trailer, various axle configurations Caterpillar C6.6 – six-cylinder – 220pk Aerzen GM-90Sm, air-cooled full-vacuum blower 26 m² with reversed rinse Stainless steel housing including stainless steel plate filter (150 micron) Belt drive or direct continuous discharging through branch lock Suction through hose Unload in Big Bag or container

Specificaties

Tank

Chassis

Engine

Pump

Filter

Safetyfilter

Driving

Payload

Loaded

Unload